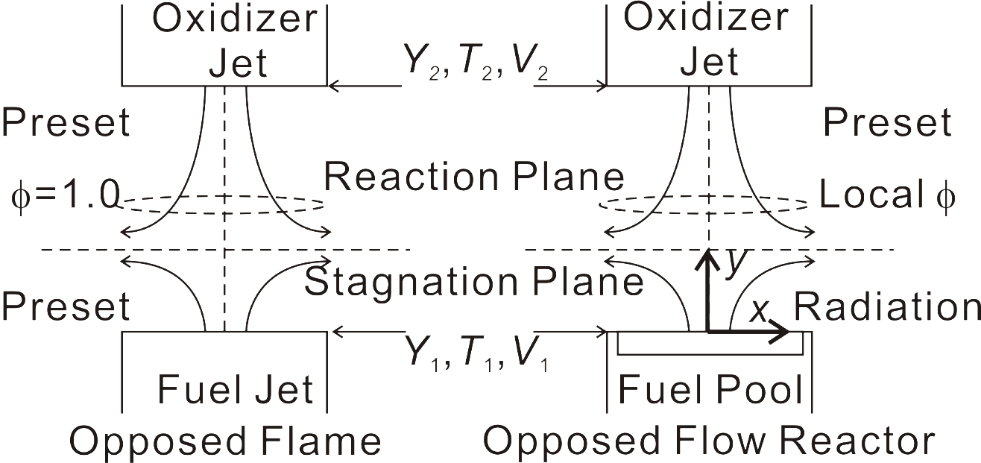

We estimate that partially reforming diesel fuel using thermal-chemical recuperation will result in a volatilized and lower reactivity fuel that may enable high efficiency RCCI to be implemented with a single stored fuel. To reform low volatility fuels like diesel catalytic and non-catalytic POx reactors must operate at an equivalence ratio of less than 3 to avoid soot and tar production leading to reactor fouling and catalyst deactivation. In order to examine such high reforming modes, from both fundamental research and application perspectives, this research explores high equivalence ratio reforming process by implementing a novel opposed flow reformer. The concept of the opposed flow reformer approximates an opposed flame, a classis flame model for fundamental combustion studies. An opposed flame usually consists two opposing jets impinging into each other. One jet contains gaseous fuel, and the other jet contains oxidizer creating a flat, thin flame sheet between the two jets. The opposed diesel reformer works in a similar way compared with opposed flame, with the difference coming from the ability to adjust the local equivalence ratio on the catalytic mesh by moving the mesh upwards/downwards. We successfully operated the reformer at various local equivalence ratio from 0.4 to 7.1 with a relative stable global equivalence ratio.

Future work of this research includes improving flame models, advanced laser diagnostics for instantaneous measurements and reactor characterizations. Furthermore, the combination of mesh location and airflow velocity will be studied to find the optimal work conditions for various purposes, and the effects of using multiple meshes will be investigated as well. Finally, in-situ reformers for practical applications will be studied based on the findings in this research.

PI: Will Northrop

Ying Lin, PhD student

Approximately 200 million internal combustion engines were produced globally in 2011, approximately 1.5 times the number of people born that same year. Engines used in transportation alone account for 22% of worldwide carbon dioxide emissions from fuel combustion; therefore, even small reductions in CO2 from engines can have significant implications for anthropogenic climate change. Improving thermal efficiency is one key method for reducing CO2 emissions from engines. Thermal- chemical recuperation using exhaust heat to reform a portion of the incoming fuel can be used to enhance diesel engine combustion. In particular, it can enable high efficiency, clean advanced combustion modes. Such modes include reactivity controlled compression ignition (RCCI), a combustion regime that uses a premixed low reactivity fuel like gasoline and directly injects a high reactivity fuel like diesel fuel into the cylinder to promote ignition.

Publications

Li, X.; Lin, Y.; Twigg, M. V.; Northrop, W. F. Opposed-Flow Reactive Volatilization Reactor for Reforming Low Volatility Fuels, Submitted to Combustion and Flame. 2016.

Li, X.; Northrop, W. F. Computational Fluid Dynamics (CFD) Investigation of an Opposed-Flow Non-premixed Liquid Fuel Reformer with Detailed Gas Phase and Porous Surface Kinetics. Spring Technical Meeting, Central States Section of the Combustion Institute. 2016.