Dimethyl ether (DME) is a potential second generation diesel fuel and propane fuel blending agent that is made by the gasification of coal, natural gas or biomass feedstocks. Production is expanding worldwide, but in the U.S. there is limited interest in DME because of technical and economic concerns. As a diesel fuel DME exhibits excellent fuel properties. The physical properties of DME are quite similar to propane so the distribution and dispensing infrastructure will be similar. Propane dispensing equipment for on-the-lot refueling is one quarter the cost of E85 and one order of magnitude less than CNG. A propane refueling station for a small fleet can literally be delivered and installed within days of ordering, and the rule of thumb is that a refueling tank will be installed at no charge for a customer using 1,500 to 2,000 gal of propane per month.

As with most technologies, “the devil is in the details”. Many alternative or renewable fuels look promising, but details marginalize them in the marketplace. Compared to diesel, or biodiesel, DME is one of those fuels: vastly superior cold starting, literally smokeless, quieter combustion, no fuel waxing in cold climates to clog fuel lines, low NOx emissions, lower well-to-wheel greenhouse gas emissions than diesel fuel, and potentially a CO2 absorber in its production. Conversion of a diesel engine to DME does not require modifications to diesel engine internal structures or components, e.g. head, block, pistons, cams, valves, manifolds, cooling pumps, turbo - the only modifications required are to the fuel system. However the fuel system modifications are not trivial and although a DME diesel conversion system should be literally retrofittable, so far only one (very expensive) kit is available. The challenges in developing engine fuel systems for DME are mainly associated with its low boiling temperature of -24°C and its low critical temperature of 127°C. Solutions to the fuel temperature problems developed by other researchers are partial and expensive. Simpler, more robust solutions are found in medium-duty SI trucks equipped with liquid propane fuel injection patented by David Bennett a co-PI on the project.

The objectives of the project have evolved to include: 1) A business/economic analysis to demonstrate the viability of a Bio-DME as a transportation fuel in areas with substantial biomass resources like Minnesota; 2) A review of life cycle greenhouse gas emissions associated with Bio-DME; 3) Use of a single cylinder Navistar DME research engine donated by the US EPA to establish baseline performance and emissions of DME; 4) Design, prototype development and evaluation of new fuel system components to improve performance and emissions of the engine when fueled by DME; 5) Conversion of a 1.9 L General Motors diesel engine to operate on DME and the evaluation of performance and emissions; 6) Establishment of links between companies with gasification technology, companies with excess biomass that might benefit from producing DME, and end users that would benefit by fleet conversion; 7) Promotion of Bio-DME as a second generation biofuel for transportation and the economic benefits of producing the fuel in Minnesota. Objective 4 is ambitious and will require more capital to complete. We plan to develop the DME fuel pump and license this development to raise revenue and demonstrate our capabilities. We are working with the University Foundation to raise additional capital so that we can move ahead with the development of other fuel system components. In particular the development of a new, lubricant free DME fuel injector will require extensive prototyping and testing. Our approach is to prepare a detailed design and protoype of each DME fuel system component and patent the technology. We hope to have a prototype DME fuel system ready for bench level evaluation in about a year. Our new fuel system components (transfer pump, high pressure pump, hoses and couplings, fuel rail and injectors) could be applied to direct injection of DME into CI engines and LPG into SI engines. A true dual fuel (propane or DME) engine then becomes possible.

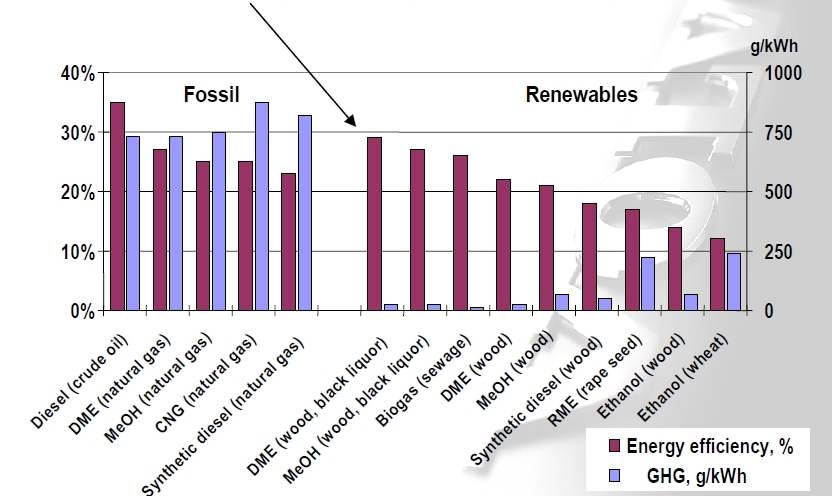

Well-to-wheel analysis for energy efficiency and greenhouse gases (Courtesy – A. Röj, Volvo Technology Corporation). These estimates include production, transport, and end use GHG emissions. KEY: DME dimethyl ether; MeOH methanol; CNG compressed natural gas; RME rapeseed methyl ester; GHG greenhouse gas.

Follow the link below for a presentation given at the 2010 IREE E3 Conference. Other related projects can be seen at the IREE website.

D. Kittelson, W. Watts, D. Bennett, S. Taff, and C. Chan. 20010.

Performance and Emissions of a Second Generation Biofuel -DME.

Center for Transportation Studies, University of Minnesota, CTS 08-10, 60 pp.

A poster based on the presentation can be seen here